Prototyping before the launch of the product can save your business time, effort, money, and other resources. Prototyping involves putting out a test product on the market or making a sample product similar to the real one to ensure no flaws and if any corrective measures need to be taken before making a full-scale investment.

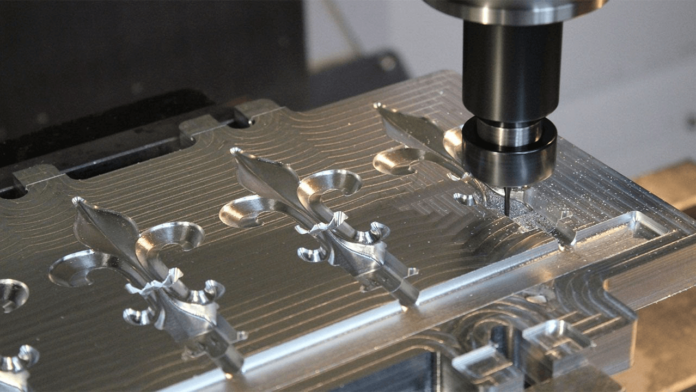

The rapid production tooling is one of the latest prototyping methods that help you launch a sample product and test the waters quickly and in an affordable manner. The process is used in low-volume injection molding and is taking over the manufacturing industry. Keep reading to know all the benefits of incorporating this in your prototyping process.

Advantages Of Rapid Tooling

There is a long list of advantages of the rapid tooling process. Here are a few top ones.

1. Saves Huge Investment And Development Costs

Rapid tooling saves significant monetary investments in product development. This process of developing a prototype is cheaper than several other processes. The materials used for producing prototypes in rapid tooling cost less, and since the material is the same as the actual product, you can test how the end product is likely to perform by spending a lot less.

Producing a prototype through rapid tooling takes less time than building one through the manual process. The saving in time also leads to reduced costs, as the longer it takes for the prototype, the more money you will have to spend on resources. So, overall, you save a significant sum with rapid tooling.

2. Less Time To Launch In The Market

As you are using rapid tooling to make a prototype, you can see the results of the real product in less time. The unnecessary time spent on building a prototype is cut down, and you can make corrective decisions faster. The faster you can get done with the prototype, the faster you will have your product in the market.

3. Experiment With The Mold

In rapid tooling, you can use various materials to make the mold and experiment with building it in different sizes and dimensions. You can also control and test the quality of different molds through rapid tooling. This becomes especially useful when unsure of the material, size, dimensions, and other product characteristics you are building.

4. More Freedom For Design Testing

With less time and money needed for churning out a product prototype through rapid tooling, you have more mental and physical capacity to test different designs and discard previous ones. If the process takes a lot of time and resources, you will not be as inclined to experiment and change things about it even though you may want to, especially if there is a deadline. But with more time available, you can see what different ideas work better.

5. Increased ROI

As you save time and costs and can quickly get to the market with well-tested and high-quality products, you will see an improved return on your investment. The low development costs, investment costs, and saving time and resources contribute towards a better ROI for the company and the product line.

Conclusion

Rapid production tooling can take your manufacturing process to a new level. It can benefit your company in the short and long run by bringing in more returns and demanding less investment. But money is not the only factor it affects. You save up on time and other resources, too, with better space for experimentation. Rapid tooling is certainly the future of prototyping.